Chiltrix V18B Variable Capacity In-Line Electric Backup Heater For Heat Pump Chillers

$553.09

In stock

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Model V18B

Dynamically Variable Capacity Automatic Backup Heater For Inline Integration w/

Hydronic Heat Pumps (Reverse Cycle Heat Pump Chillers)

The V18B

output is modulated in real time from 0-18,760 BTU (0-5.5 kW) in 1% increments

to avoid overshoot and maximize the percentage of total heat provided by the higher

COP heating source (the compressor).

The

V18B dynamically variable capacity inline (tankless) backup heater is designed

for use with intelligent variable capacity hydronic (air-to-water) heat pumps

such as the Chiltrix CX34.

The V18B variable capacity backup heater automatically adjusts its BTU (Watts)

output to target an exact match to any shortfall of heating, in real time.

The V18B backup heater provides between 0 – 18,766 BTU, depending on the

requirements of the moment.

output to target an exact match to any shortfall of heating, in real time.

requirements of the moment.

Depending

on your location, building envelope values, and other factors such as weather,

you may need to consider an integrated backup heat solution.

If

backup heat is needed in your climate, the V18B backup heater will save energy

compared to the typical options, by providing only the amount of backup heating

BTUs needed.

The

V18B dynamically variable backup heater maximizes the percentage of

compressor-generated high efficiency heat (COP ~2.5 to 3.5 or higher) and

reduces the consumption of less efficient resistance backup heat (COP

=/<1.0).

As

a fully integrated and automatic system, the V18B also avoids the need for

unsafe “portable” heaters, has a tiny footprint and little pressure

drop.

Consult

with your Chiltrix sales engineer or HVAC professional to see if backup heat is

needed for your application and location.

Compare

to the Standard Air To Water Backup Heating Approach:

Prior to the introduction of the

V18, the typical and globally-accepted standard backup heat solution for air-to-water

(hydronic) heat pumps has been to mount a small electric water heater tank,

with thermostat & element, in series on the supply side of the loop, to add

extra heat when the heat pump cannot keep up with the load. In this example a

controller enables the tank thermostat/heating element when loop temperature

goals are not met. While this works and is the common global technique for

hydronic backup heat, thermal lag in the backup heat tank and hysteresis of the

element/thermostat generally cause significant overshoot and undershoot of the

temperature settings, with swings of up to 10 ºF above or below the target

being common.

While providing capability to supply

heat under conditions where the heat pump compressor cannot by itself handle

the heating load, in the standard solution, comfort is acceptable but

efficiency is lower than it could be due to temperature over-shoot. For

example, when the tank-type backup heater overshoots, any extra heat provided

(low-efficiency resistance heat) unnecessarily lowers the overall system

efficiency by providing heat that could have been provided by the compressor at

a much higher efficiency.

Modulating tankless heaters have

also been tested for radiant and hydronic backup applications but severe

pressure-drop issues have proven them to be an undesirable alternative.

Further, commercially available tankless heaters are not compatible with cold

water running through them during the cooling season and as a result, they

suffer condensation problems.

What’s

New & Different About The V18B Variable Backup Heater?

The patent-pending V18 dynamically

variable inline (tankless) backup heater solution avoids overshoot or

undershoot issues by matching its output to a capacity shortage (BTU

shortfall). For example, if a certain BTU is needed, the V18 targets exactly

that amount of BTU. The V18 can dynamically adjust its output in real time. As

the load changes, and heating shortfall changes, the V18 changes with it

dynamically, reconfiguring its BTU output to match the load shortfall. The V18

is always targeting the precise amount of extra heat needed, allowing the

compressor to provide the highest possible percentage of the heating

requirement and providing stable heat values in the hydronic loop. So

aside from not requiring the footprint/space needed for a backup tank and

avoiding the excessive pressure drop and condensation issues of a tankless

heater, the V18 saves a lot of energy by keeping the loop temperatures stable

and allowing the compressor to provide the highest possible percentage of the

heat.

Click Here – V18

Specification Sheet

How Does The V18 Hydronic/Radiant Backup Heater

Work?

Work?

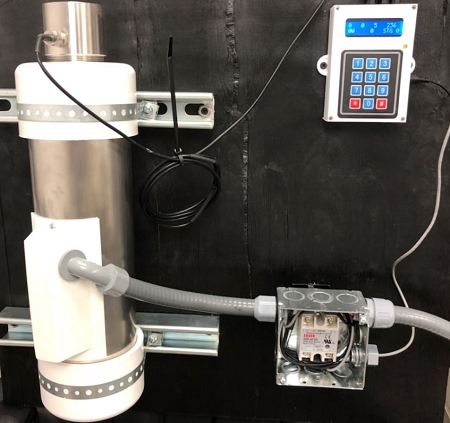

The patent-pending V18 uses a

special long-life and replaceable Incoloy resistance heating element rated at

up to 5,500w (18,766 BTU). The element is installed in a linear configuration

inside a 2″ stainless steel tube with 2″ NPT female threaded

connections on each end. The tube is heavily insulated and wrapped by a

stainless steel outer cover. A special solid state relay controller is used to

vary the watts of the element from 0w to 5500w in increments of around 1%. The

solid state relay is controlled by information from the heat pump to accurately

target the BTU shortfall. The element output can be adjusted on the fly, for

example at 55w (187 BTU), 110w (375 BTU), 165w (562 BTU), and so forth up to

the full power of 5500w (18,766 BTU) as needed to match the requirement. The

Chiltrix heat pump, which is a variable capacity unit, modulates its capacity

based on continuously recalculating and adjusting its output to match the load.

In this control process, the Chiltrix unit is also aware of any heating

shortfall, and knows the BTU amount of such shortfall. When controlled by the

Chiltrix heat pump, the V18 can be targeted to match its output closely to any

BTU shortfall in real time.

In all heat pump systems including

Chiltrix, ultimately the “return” water temperature (or buffer tank

temperature) directly or indirectly generates a call for a capacity increase or

decrease. If a backup heater overshoots its target as is common with the

standard tank approach, return water is at that time artificially higher,

causing the heat pump to think the load has decreased, causing the heat pump to

slow or stop. This action recursively creates the need for more backup heat and

ultimately means a much higher than needed percentage of heat comes from the

low efficiency backup unit than would be used if overshoot did not occur.

The V18 dynamically modulating heater

eliminates this problem by avoiding overshoot.

This allows the higher efficiency heat source (the compressor) to provide a

much larger percentage of total heat during this time and minimizes the amount

of lower efficiency of resistance heat applied by the backup source which

raises the average system COP significantly.

Installation

& Safety:

The V18 heater has a small footprint

in a compact tubular form factor ~19″ in length and ~6″ in diameter

and is connected to a small low voltage control unit measuring approximately

5″ x 5″ x 1.5″. The design of the V18 is such that it cannot

operate if there is no heating shortfall, if outdoor temperature is above a

predefined setting, if water flow is below a minimum GPM required, or if the

water temperature (or the unit itself) rises above a maximum set point. Low

voltage controls in communication with the Chiltrix heat pump send power

modulation signals to the solid state relay. Within the V18 there is a thermal

overload safety switch that will interrupt power to the backup heater and must

be manually reset if a maximum backup heater internal temperature is reached.

The Incoloy heating element, the solid state relay, and the thermal over-limit

switch are all UL Listed. Assembly by a qualified and licensed installation

professional is required.

Requires >/= 25a circuit with GFCI breaker, 208-240v. Multiple V18

units can be installed with a single heat pump if needed.

Practically No Pressure Drop:

@ 7 GPM = 0.000427775 ft.

@ 14 GPM= 0.001438843 ft.

Additional information

| Weight | 8 lbs |

|---|---|

| Dimensions | 8 × 8 × 20 in |

Reviews

There are no reviews yet.